Prototyping – First step to a successful production

The production process is like a long chain composed by different links. Turning the idea into an article requires conscientious planning in each of the phases. In this article we tell you what prototype manufacturing is, and why it is an essential link in product development.

What is a prototype?

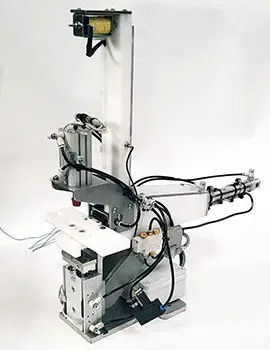

A prototype is the first sample of a product which is taken as a model to ensure the manufacturing process of other products like that. Despite the most reliable sample can be made with the same material as the final production, it also can be made with different materials such as plastic, aluminium, different types of resin and other materials.

What are the benefits from prototyping?

It lets you be sure the design is according to customer’s requirements like functionality, volume and geometry.

Moreover, it is useful to detect possible mistakes or weak points from the design phase.

As consequence, after proving all its characteristics like mechanical resistance, hardness, elongation and other qualities, it is possible to avoid high expenses from the manufacturing process and materials thanks to this previous sample.

It is highly recommended to keep the first samples in a safe place and near your reach.

To conclude, prototyping is an essential link to validate the manufacturing process and reach a quality level according to our customer’s requirements. In MEILAV we carry out all the process from the design phase to the final delivery to our customer, following the current laws. We make use of all necessary technology and materials to ensure reliable prototyping. Feel free to contact us without obligation.